Features:

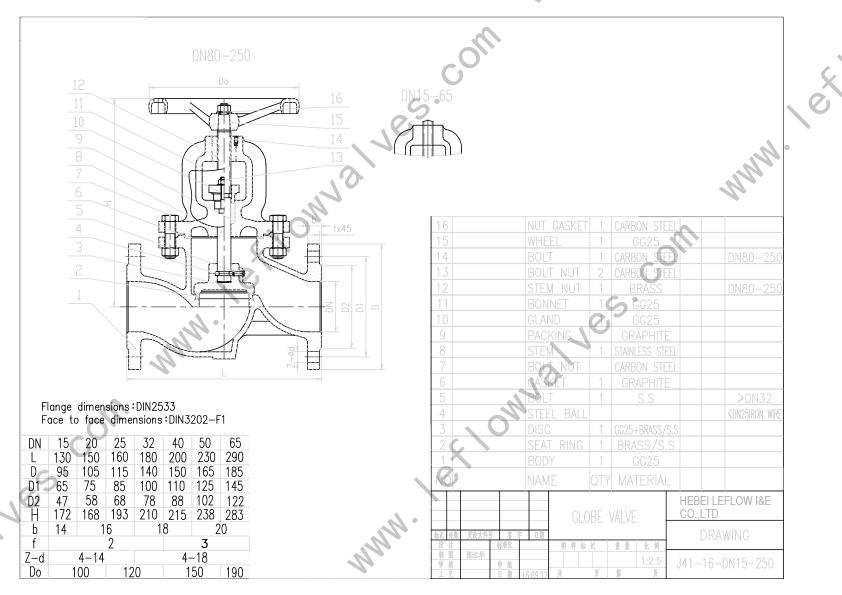

Leflow is offering Straight and Angle type globe valve, Size DN15 to DN300,PN16,The Sealing is commonly Stainless steel, Flow direction is from bottom to up. The stem is usually 2Cr13,because of its rigidity. Fusion bonded epoxy is common coating.

Cast iron globe valves are commonly used in industrial piping equipment to control and regulate the flow of fluids. It is mainly composed of body, bonnet,disc,Stem and other accessories.By rotating the stem, the disc will contact or separate to seat, so as to control or regulate flow of fluid.

Cast iron globe valves are suitable for liquid or gas piping systems under medium and low pressure. It can handle a variety of media, such as water, oil, steam and so on.

Its key benefits are as following:

1. Simple and compact structure: Cast iron globe valve is composed of a small number of parts, easy to install and maintain.

2. Good sealing performance: different materials are used for the seat and valve disc, and suitable sealing materials can be selected according to the requirements of the medium to ensure excellent sealing performance.

3. Good flow performance: the channel design of the valve seat is reasonable, and the flow resistance is small, so that the flow of the fluid is not hindered.

4. Strong corrosion resistance: the surface of the cast iron globe valve body is treated with corrosion protection, which can effectively prevent the corrosion of the medium.

5. Fast opening and closing: the opening and closing speed of the valve is fast, which can quickly cut off or restore the flow of fluid.

6. Strong bearing capacity: Cast iron globe valve is made of cast iron material, strong pressure resistance and high bearing capacity.

Installation and Maintenance Tips

1.Proper Installation: Ensure correct alignment during installation to avoid operational issues and ensure optimal performance.

2.Regular Inspection: Periodically inspect the valve for signs of wear, corrosion, or damage.

3.Lubrication: Keep moving parts well-lubricated to reduce friction and wear.

4.Cleaning: Prevent debris buildup by keeping the valve clean.

5.Timely Replacement: Replace any worn or damaged parts promptly to maintain the valve’s performance and extend its lifespan.