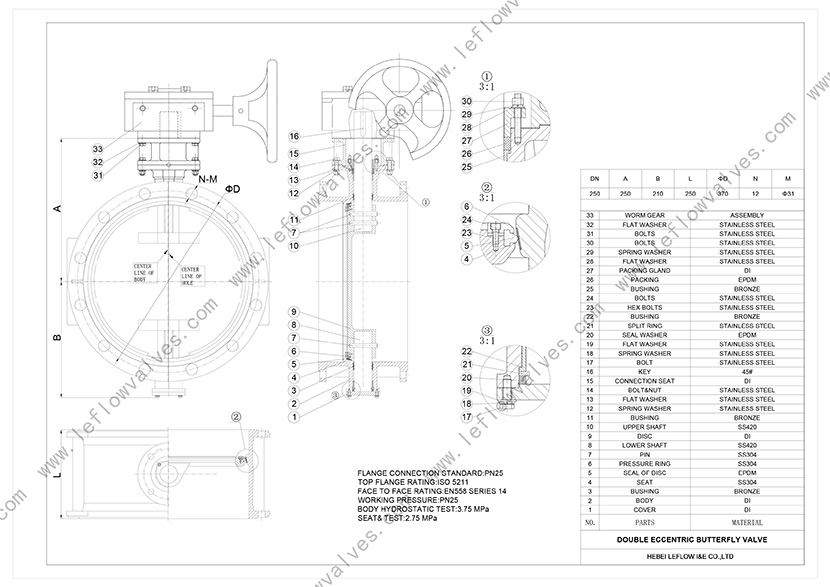

Name: Double eccentric butterfly valve

Another name: High performance butterfly valve

Applicable: Water plant, power plant, steel plant smelting, chemical industry

Features: Longer life and good stability

Features:

Leflow is providing high quality 2 (Double)-offset butterfly valve. We produce double eccentric butterfly valves with diameters ranging from DN100 to DN1200.

Double offset uses two separate offsets to achieve a bubble-tight. One of the offsets is the location of the valve shaft relative to the centerline of the bore. Another offset is between the centerline of the disc/seat sealing surface and the shaft.

This structure make the valve has following benefits:

1. Double Eccentric structure ensures low operating torques with zero leakage performance;

2. Inner and outer surfaces of the valve are coated with fusion bonded epoxy,and Its thickness can be adjustable;

3. Low moments are obtained by decreasing the friction through self-lubricating bushings;

4. Can bear high stretching stresses on the pipeline through the ductile iron body and disc;

5. High impact resistance.

6. Pressure loss is at minimum level by double shaft design.

7. Sealing gaskets fasten by bolt can be replaced at field condition;

8. With the o-rings on the bearing bushings, disc pin holes are protected against corrosion (Dry shaft);

9. Retaining ring is assembled to the disc with imbus bolts, the disc is protected against corrosion by placing o-rings under the bolts.

10. Stainless steel welding seat can reach better sealing

High Performance 2-Offset Butterfly Valve

Double eccentric butterfly valves belong to the category of regulating and shut-off devices on waterway pipelines, also known as high-performance butterfly valves. They are primarily suitable for drainage systems in water plants, power plants, steel smelting, chemical industry, water source engineering, environmental facilities construction, etc., especially on waterway pipelines, where they are used as regulating and shut-off devices. Compared to centerline butterfly valves, double eccentric butterfly valves are more resistant to high pressure, have a longer lifespan, and exhibit better stability.

Operating principle

Double eccentric butterfly valves are further improved based on single eccentric butterfly valves. The structural feature of double eccentricity is that the axis of the valve stem is offset not only from the center of the disc but also from the center of the body. The effect of double eccentricity allows the disc to immediately disengage from the valve seat after the valve is opened, substantially eliminating unnecessary excessive compression and scraping between the disc and the valve seat, reducing the opening resistance, lowering wear, and improving the valve seat’s lifespan. The substantial reduction in scraping also allows double eccentric butterfly valves to adopt metal valve seats, enhancing the valve’s application in high-temperature fields.

Structural Features

Reasonable design, compact structure, easy installation and disassembly, and convenient maintenance.

Adopting an eccentric structure to reduce friction of the sealing ring and prolong the valve’s service life.

Completely sealed with zero leakage, suitable for ultra-high vacuum conditions.

Replacement of disc sealing rings, discs, shafts, and other materials can be adapted to various media and different temperatures.