Features:

Leflow’s Tilting disc check valve is Double Eccentric structure, normally with counterweight and hydraulic damper.

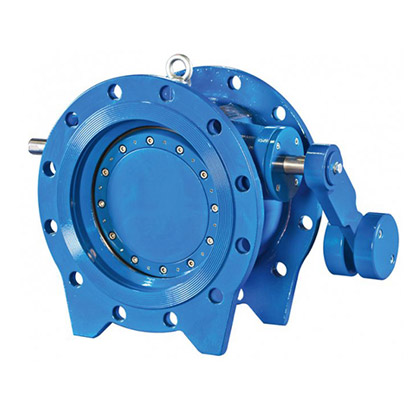

Tilting Disk Check Valves,also called butterfly check valve, is a cost-effective valve with a unique design that provides excellent tightness and minimizes water-hammering. It is designed for drinking water and other neutral liquids, and commonly installed in pumping applications to prevent backflow in the system. The opening pressure will be very low.It is mainly used for water industry, irrigation, municipal engineering, drinking water engineering and etc

The key benefits are as following:

1.Ensures ZERO leak with the “T” section ring fixed to the outer diameter of the disc fully facing the seat surface inside the body perimeter made of stainless steel welding.

2. The sealing that can be made of EPDM/NBR/VITON,which can be replaced easily on field conditions.

3. Inner and outer surfaces of the valve is coated with fusion bonded epoxy.

4. Low toqure can be achieved by decreasing the friction through self lubricating bushings.

5. High impact resistance.

6. Pressure loss is at minimum level by double shaft design.

7. Counter weight allows installation of both horizontal and vertical pipes on the right and left sides of the mill, counterweight, and lever on both sides of the check valve.

8. The disc opens depending on the flow rate and moves freely depending on the flow.

9. With the o-rings on the bearing bushings, disc pin holes are protected against corrosion (Dry shaft).

Leflow’s tilting check valves are designed to meet the stringent demands of industrial fluid handling applications, providing reliable flow control and protection against backflow. With their robust construction, efficient operation, and versatility, Leflow tilting check valves are a trusted choice for industries requiring secure and efficient flow management solutions.

China tilting check valve: Our factory specializes in producing high-quality tilting check valves, including tilting disk check valves and tilting disc check valves. We are one of the leading tilting disc check valve manufacturers and suppliers, offering a wide range of products such as tilting disc wafer check valves. Our tilting disc check valves are known for their reliability and durability, suitable for various applications. As a trusted tilting check valve factory, we ensure that each tilted disc check valve meets industry standards for performance and quality.

Tilting Check Valve is designed for efficient backflow prevention in water, wastewater, and industrial pipeline systems. It features a robust structure that ensures reliable sealing and minimal pressure loss during operation.

Tilting Disc Check Valve Design

The Tilting Disc Check Valve adopts an advanced design that allows smooth opening and closing with low flow resistance. The Tilting Disk Check Valve combines strength and precision, making it suitable for large pipeline diameters.

The Double Eccentric Tilting Check Valve and Double Eccentric Design Check Valve options enhance sealing performance and extend service life under high-pressure conditions.

Structure and Material Features

Engineered for durability, this valve offers several advanced features:

Counterweight Tilting Check Valve for controlled closure and reduced water hammer

Hydraulic Damper Check Valve for stable operation in pumping systems

Zero Leak Tilting Check Valve with precision-machined sealing surfaces

Low Torque Tilting Check Valve for energy-efficient operation

Self-lubricating Bushing Check Valve to minimize wear and maintenance

T Section Ring Sealing Check Valve for tight sealing performance

Dry Shaft Design Check Valve for improved corrosion resistance

Fusion Bonded Epoxy Coated Check Valve for long-term protection in harsh environments

Corrosion Resistant Tilting Check Valve for chemical and seawater applications

Low Pressure Drop Tilting Check Valve ensuring smooth fluid flow

Applications

The Tilting Check Valve is widely used in municipal and industrial projects, such as:

Tilting Check Valve for Drinking Water

Tilting Check Valve for Municipal Water Systems

Tilting Check Valve for Irrigation

Tilting Check Valve for Pumping Applications

Tilting Check Valve for Water Industry

Tilting Check Valve for Water Treatment

Tilting Check Valve for Wastewater Use

Tilting Check Valve for HVAC / Cooling Systems

Tilting Check Valve for Industrial Fluid Handling

Tilting Check Valve for Pipeline Backflow Protection

Technical Specifications

Standard sizes and pressure ratings include:

Tilting Check Valve DN200 DN300 DN1200

Tilting Check Valve PN10 PN16 PN25

These models conform to BS EN 12334 Tilting Check Valve and Face-to-Face Standard EN558-2 Series 14 for international compatibility. Connection options include Flanged Tilting Check Valve, Wafer Type Tilting Check Valve, and Counterweight Lever Tilting Check Valve.

Procurement and Customization

As a professional Tilting Check Valve Manufacturer and Tilting Check Valve Supplier, LeFlow provides reliable quality and flexible OEM service. Customers can:

Buy Tilting Check Valve directly from the factory

Order customized sizes through OEM Tilting Check Valve service

Enjoy competitive Tilting Check Valve Price for large projects

Source globally through Tilting Disc Check Valve Factory and Tilting Disk Check Valve Exporter channels

Tilting Check Valve combines durability, precision engineering, and wide adaptability. Whether you need a Wafer Tilting Check Valve for compact pipelines or a Double Eccentric Tilting Check Valve for high-pressure systems, this product ensures efficient backflow protection and long service life.