Features:

Leflow’s Inverted Pressure Balance Lubricated Plug valve has following characters:

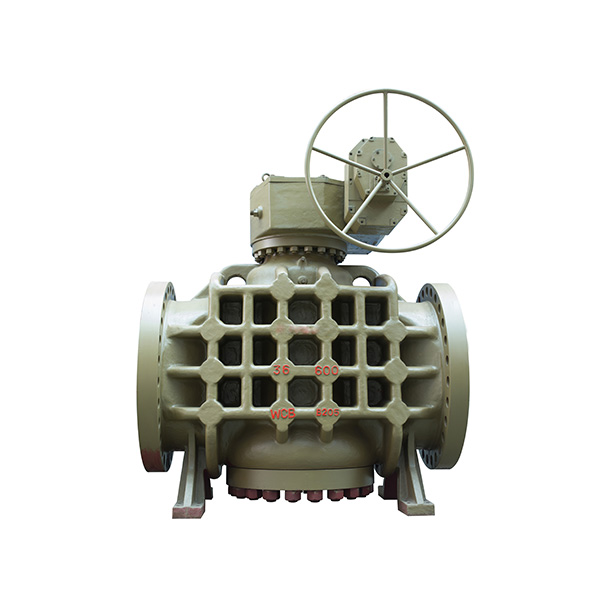

1.Top entry design ,easy for online maintenance;

2.Grease sealing design,with good sealing performance;

3.Sealing with adjustable design;

4.Bidirectional seals,no limitation on the flow direction

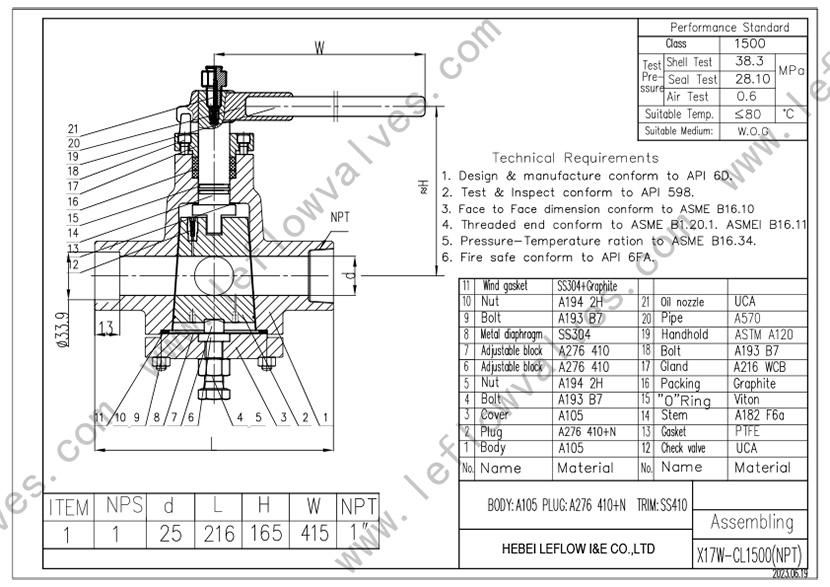

Plug valve is a valve that relies on the rotation of the plug body (also known as the plunger) to achieve the function of opening and closing. It consists of body,plug with a through hole,Stem and Seat.

The main uses of the plug valve include cutting off, distributing and changing the flow direction of the medium. In addition, it can also have the function of throttling according to the different medium properties and the sealing surface material of the valve. The use of plug valves can reduce the number of valves in the piping system and the required connection fittings, thus simplifying the design and reducing costs.

The sealing method of the plug valve is usually sealed by direct contact between the plug body and the valve body, but because the sealing performance of this method is relatively poor, the plug valve is not suitable for high pressure and large diameter application. For low pressure and small bore situations, plug valves are an economical and practical option.

The working principle of the plug valve is to control the flow of the medium by rotating the plug body. When the plug body is closed, its raised part on the plug is fully fitted to the seat, forming a completely airtight enclosed space. When the valve needs to be opened, the bearing is rotated by the operating mechanism, which drives the plug body to rotate, so that the raised part is separated from the seat, and the medium can flow through the valve. By adjusting the rotation Angle of the plug body, the flow rate and pressure of the medium can be effectively controlled.

Its key benefits are as following:

1.Plug valve is with light torque, and can be operated easily and quickly;

2. Fluid resistance is small.

3. Structure is simple, relatively small appearance, light weight, easy maintenance.

4. Good sealing performance.

5. No limit to installation direction, the flow of the medium can be arbitrary.

6. No vibration, small noise.