Features:

The disc of Knife gate valve is flat, but the disc edge is knife-type oblique,Like the blade of knife, which can cut off the fluid easily,even if there are some solid particles. Because of its compact wafer structure, it is mainly for low pressure application. The ends can be Wafer, Lug and Flange types.

Knife Gate valve is commonly used in following application:

Pulp and Paper Industry, Mining,Power Plants,Food and Beverage, Chemical Plants and Water Treatment plants.

Each part of valve is designed specially and has following benefits:

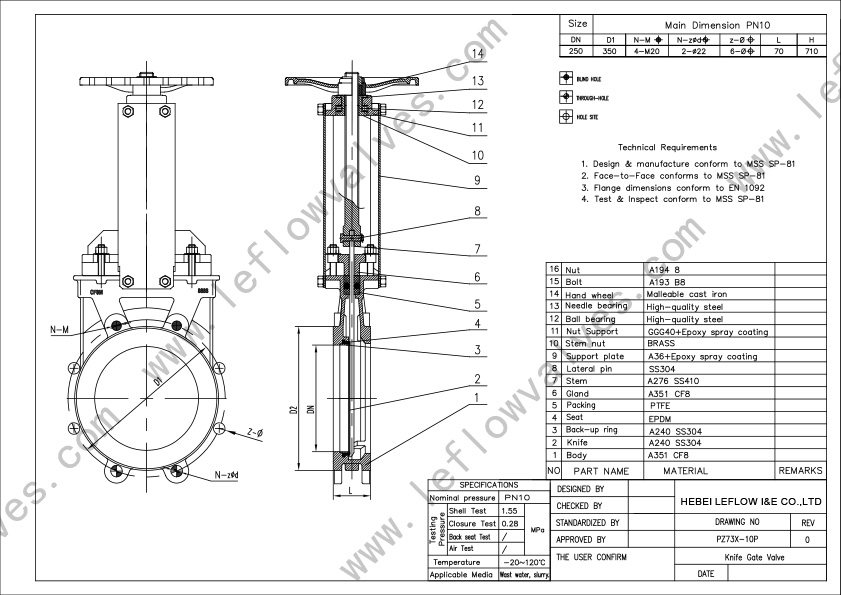

Body

The body design of knife gate valve has the advantages: simple,compact and reasonable structure,smooth port,small flow resistance, light weight, easy installation etc.

Disc

Standard AlSI 304 or 316 stainless steel gate is grinded and polished smoothly as mirror,which can effectively avoid damage of packing and seat during open and close . The bottom of the gate edge is machined to a bevel,so that it cuts through the solids for a tighter seal in closed position.

Seat (resilient)

The seat can be metal and soft.Metal is usually welded onto body, the common material is 13Cr and Stellite. The Soft seat is mainly NBR,EPDM,PTFE, Viton, Silicone etc. Unique design that mechanically locks the seal in the internal of valve body with a stainless steel retainer ring.Normally it is unidirectional seal design,and bidirectional seal as requested.

Packing

Several layers of braided packing with a strong gland ensuring a tight seal. Available in a range of materials: Graphite, PTFE,PTFE+KEVLAR etc.

Stem

Standard stainless steel stem with good corrosion resistance offers a long service life. For rising stem only, a stem protector can be provided for additional protection against dust while the valve in the open position.

Operation modes

Lever, handwheel,chain wheel,Bevel Gear and Pneumatic or Electric Actuator.

Epoxy Coating

AII cast iron and cast steel valve bodies and components are epoxy coated,well protecting inner port and surface against corrosive and dirty conditions for longer service life. The standard coating colour is RAL5010

Accessories and Options

Deflection cone,V or pentagonal port,injection holes,Locking device, Solenoid valve, Positioner, Limit switches,Proximity switches,Magnetic switches,Air filter,Stem extension etc.

Applicable temperature range

| Seat | ||

| Material | Max. Temperature (°C) | Application |

| Hard sealing | ≥200°C | Low density and high temperature medium |

| EPDM(E) | 120°C | Acidic and non-oil medium |

| Nitrile(N) | 80°C | Oil and wear resistance |

| FKM/Viton(V) | 180°C | Chemicals

High temperature liquid |

| PTFE(T) | 150°C | Resistance of corrosion and alkailine substances |

| Packing | ||

| Material | Max. Temperature (°C) | PH |

| Ramie PTFE packing | 130°C | 5-11 |

| PTFE Braided packing | 240°C | 2-13 |

| PTFE+KEVLAR | 260°C | 0-14 |

| Graphite packing | 550°C | 0-14 |

| Ceramic fiber | 950°C | 5-9 |

In the world of industrial valves, there are various wafer type knife gate valves and wafer style knife gate valves that serve crucial functions. Specifically, the knife gate valve wafer type and the wafer knife gate valve are highly regarded for their efficiency. Additionally, the term wafer gate valve is sometimes used interchangeably, but it’s important to note the distinction between it and other gate valve types. When discussing gate valve wafer type configurations, one must consider the different knife gate valve types available, as each serves a unique purpose. Ultimately, selecting the right gate valve type for a particular application is crucial.