Features:

Leflow is offering Wafer Check Valve with following options:

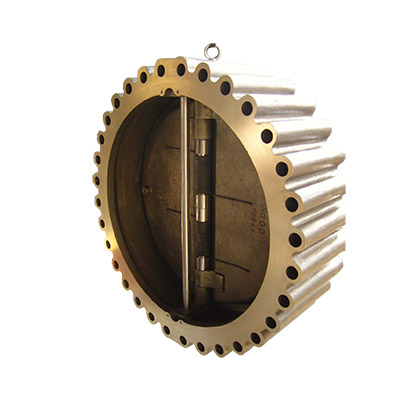

1.Body ends can be WAFER,FULL-LUG and Double Flanged;

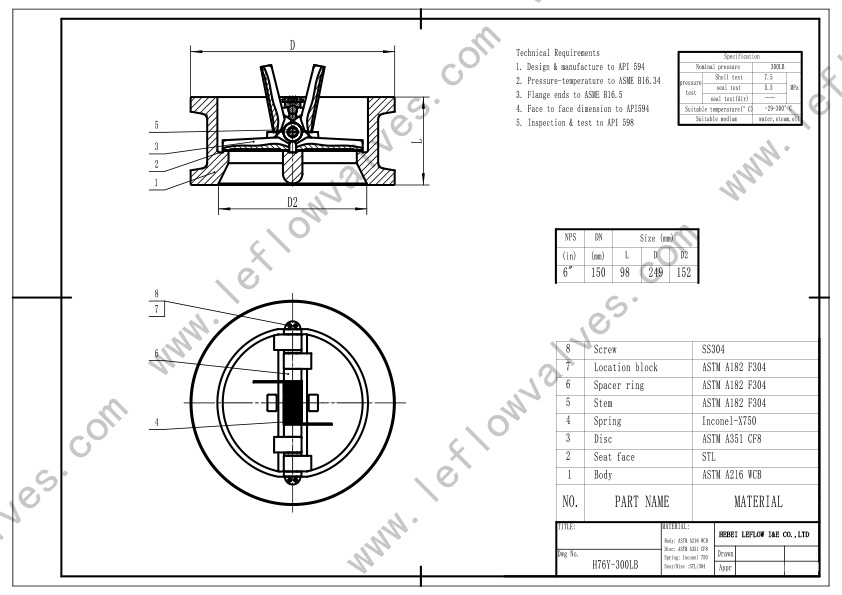

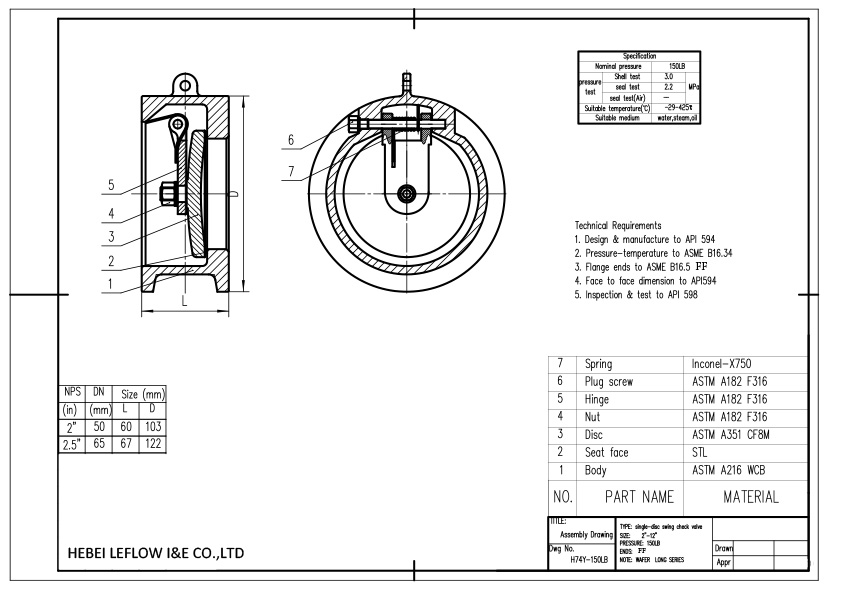

2.Disc can be DUAL-PLATE,SINGLE SWING,TILTING and AXIAL FLOW type;

3.Seat can be Metal or soft(NBR,EPDM or VITON);

4.The pin can be built inside of valve, thus no exterior leakage possible.

Wafer check valves use a swinging disc to allow or block flow, the inner parts are all in the pipeline. Their design allows them to be assembled in extremely tight spaces,where the flanged check valve can not be used.It is widely applied in various industries, including chemical, petroleum, natural gas, power, etc.

Its key benefits are as following:

1. Compact Structure: Cast Steel Wafer Check Valve adopts a wafer-type connection, which is easy to install, compact in structure, and occupies a small space.

2. Quick Response: Due to the combined design of spring and disc, the valve can respond quickly to changes in fluid flow direction and close the valve to prevent backflow, thus reducing energy loss and oscillation.

3. High Temperature and Corrosion Resistance: Cast Steel Wafer Check Valve can be made of different materials, such as carbon steel, stainless steel, according to the characteristics of the working media to adapt to different working environments.

4. High Sealing Performance: Cast Steel Wafer Check Valve has good sealing performance, effectively preventing media leakage.

5. Low opening pressure. It just needs little pressure to open the valve.