Features:

Leflow is manufacturing Steel Globe valve as EN 12516. For big size, to easy operation, We suggest Reverse flow type(The fluid will flow from up to down). Straight,Y-Type and Angle type are available; Bellow seal globe valve is also optional. The plug can be Plug, Needle and throttling(Parabolic) type.

The cast steel globe valve is operated by lifting or lowering the stem. It is mainly used to control the fluid in the pipeline, with strong pressure capacity, good sealing characteristics. Cast steel globe valves are suitable for a variety of working conditions, including high temperature, high pressure, strong corrosive media. It can be installed anywhere in the pipeline and adjust the pressure and flow of the fluid as needed. The valve is widely used in fluid control systems in petroleum, chemical, electric power, metallurgy and other industries.

Cast Steel Globe valve has following key advantage:

1.Strong cast steel material: cast steel globe valve is made of high-quality cast steel material, has excellent corrosion resistance and high temperature resistance, can adapt to a variety of harsh conditions.

2.Good sealing performance: The cast steel globe valve is equipped with a sealed structure, through the contact between the valve plate and the seat, to ensure that the fluid completely stops flowing when the globe valve is closed to prevent leakage and leakage.

3.Accurate flow control: Cast steel globe valve by lifting or lowering the stem, to achieve valve opening and closing, so as to accurately control the fluid on and off. Easy to operate, small operating torque.

4.Reliable bearing capacity: Cast steel globe valve is made of cast steel material, with high strength. It can withstand high pressure and shock loads to ensure the safe operation of the system.

Maintenance Tips for Cast Steel Globe Valves

1.Regular Inspection: Conduct regular inspections to check for signs of wear, corrosion, or damage.

2.Lubrication: Ensure that the moving parts of the valve are properly lubricated to prevent friction and wear.

3.Cleaning: Keep the valve clean to avoid the buildup of debris, which can affect its operation.

4.Replacement of Worn Parts: Replace any worn or damaged parts promptly to maintain the valve’s performance and extend its lifespan.

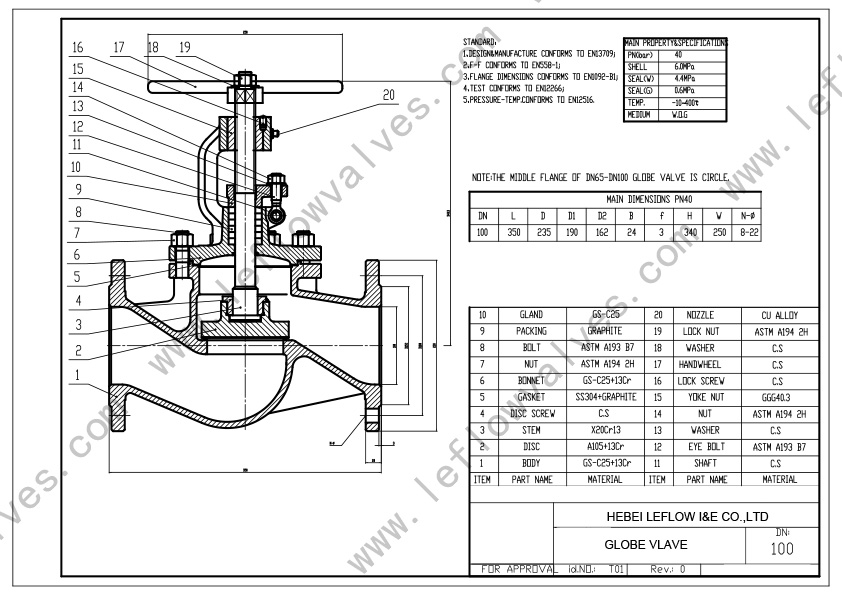

High Performance Cast Steel Globe Valve DIN

Cast Steel Globe Valve DIN series is designed for high-performance industrial applications, offering reliable flow control and shut-off capabilities. Available in Stainless Steel Globe Valve, Carbon Steel Globe Valve, and Alloy Steel Globe Valve, these valves meet the highest standards for durability and corrosion resistance. They are suitable for power plants, water treatment systems, chemical industries, steel plants, environmental facilities, and pipeline shut-off applications.

Operating Principle

The Rising Stem Globe Valve and Non-Rising Stem Globe Valve designs ensure precise flow control. The Bellows Seal Globe Valve and Metal Seat Globe Valve reduce leakage and wear, providing stable operation under High-Pressure Globe Valve and High-Temperature Service Globe Valve conditions. Handwheel Operated Globe Valve ensures easy manual operation, while Easy Maintenance Globe Valve and Replaceable Sealing Gasket Globe Valve features reduce downtime.

Structural Features

-

Compact and reasonable structure, easy installation and disassembly.

-

Flanged Globe Valve, Threaded Globe Valve, Butt Weld Globe Valve, and Lug Type Globe Valve configurations provide flexible installation options.

-

Flow Control Globe Valve, Shut-Off Globe Valve, and Isolation Globe Valve functions for precise and reliable operation.

-

Sizes from Cast Steel Globe Valve DN50-DN1200 with Cast Steel Globe Valve PN16, Class150 pressure rating.

-

Fully compliant with DIN Standard Cast Steel Globe Valve, EN Standard Cast Steel Globe Valve, ISO Certified Globe Valve, and CE Certified Globe Valve. Designed according to Face to Face DIN3202 F4 Globe Valve specifications.