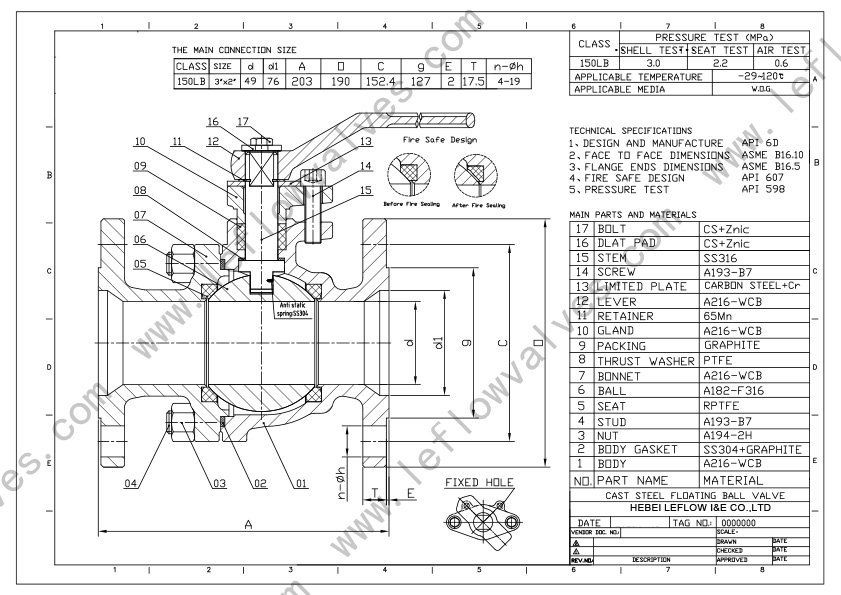

Leflow’s floating ball valve is manufactured as API 6D and BS 5351, with precise machining and high performance. Both metal seat and soft seat are within the scope, Hereunder is our advantage:

1.The body can be casting and forging, Bolted or Full-welded cap;

2.The structure can be 1PC,2PC,3PC type;

3.The passway can be 2-way, 3-way,4-way and Y-port 120D or 135D;

4.Mounting Pad is available, to fit Gear box and Actuators;

5.Extension Stem is optional;

6.Low emission packing according to ISO 15848 is optional;

7.Spring loaded packing is optional;

8.Jacket design is optional;

9.Full bore or Reducing Port are optional;

10.Anti-static and Blowout-proof design;

11.Locking device is optional;

12.Seat can be PTFE/ RPTFE/ NYLON/DEVLON/Derlin/PEEK/PPL and other metals

A ball valve is a flow control device which uses a hollow, perforated, and pivoting ball to control fluid flowing through it.It is open when the hole through the middle of the ball is in line with the flow inlet, and closed when it is pivoted 90 degrees by the valve handle, blocking the flow.It usually turns 90D,120D and 135D. The valve is widely used in petroleum refining, long-distance transportation pipeline, chemical, paper making, pharmaceutical and electric power.

Leflow’s Floating ball valve is designed as ball is movable. Under flow pressure, The ball floats to downstream slightly and press to body seat to form a tight seal.