Features:

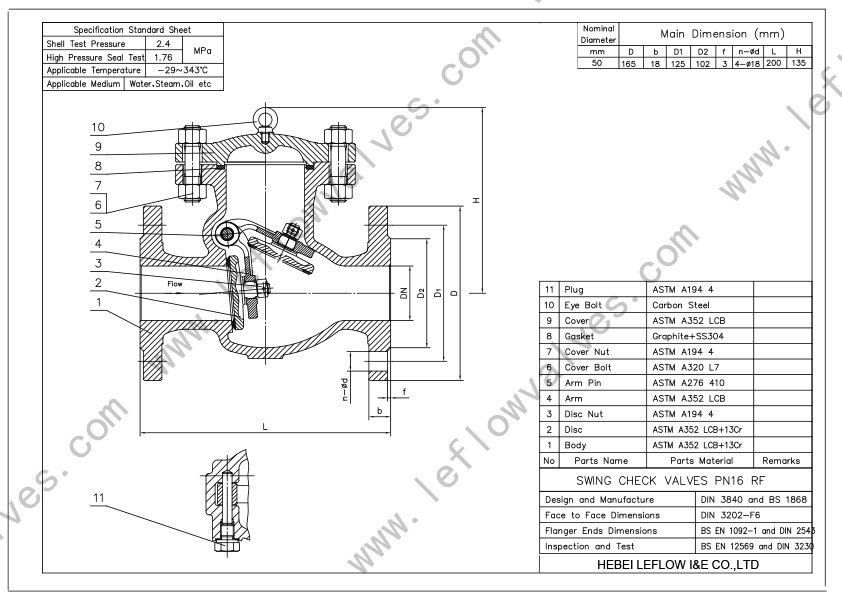

Leflow’s DIN standard Cast Steel Check valve includes Lift and Swing type. The End to end length of Lift type conforms to DIN3202 F1/F2(EN558-1 series 1/2),size ranges DN15 to DN300; Swing check valve complies to DIN3202 F6/F1/F2/F8 (EN558-1 Series 48/1/2). The seat is commonly INTEGRAL.The cover is bolted when pressure is small and middle,Pressure seal type for high pressure and big size is recommended.When pressure and size is big, counter weight is necessary, sometimes, Hydraulic damper is selected, to protect valve seat and pipeline.

The cast steel swing check valve is an automatic valve, when the fluid comes as defined, the disc leave the seat and valve is open, the more the pressure, the bigger open(≤90D) the disc, when the big pressure comes bigger than coming ones, the disc will come back to seat, and close the valve, the bigger the pressure difference, the better sealing performance it will be. This kind of valve is used to control the flow of different media such as water, oil, steam, and gas, and achieve switching and regulating control under different process conditions.

It has following benefits:

1.The disc is hinged inside the body,No stem leak points;

2.Good sealing performance: It has excellent sealing performance, effectively preventing media leakage and improving the safety and stability of the pipeline system.

3.Flexible operation: It adopts a rotary method for opening and closing, making the operation flexible, convenient, and highly reliability

4.Can be installed in either vertical or horizontal applications.

5.Head loss is lower compared to other type of check valves.