Features:

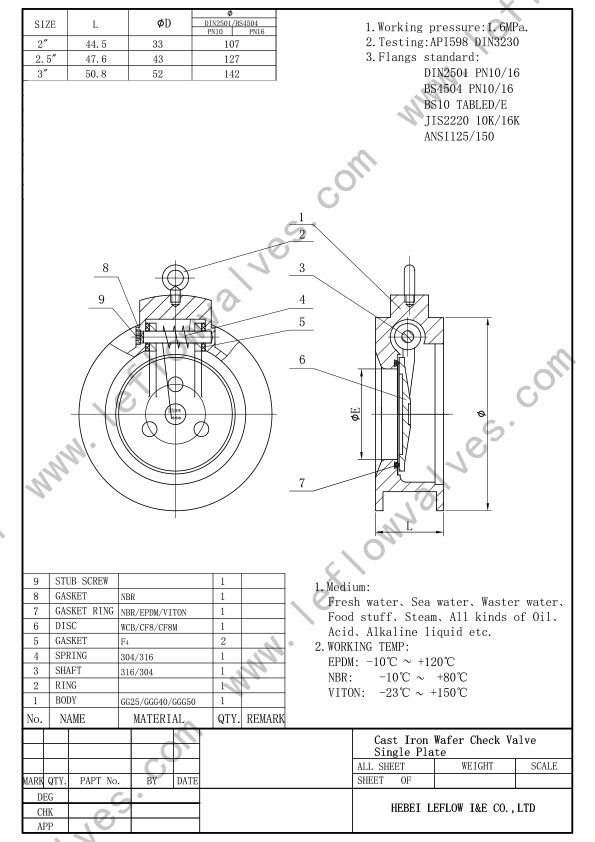

Leflow is manufacturing Cast Iron Wafer Check Valve with DIN3202 K1 and API 594A standard, Size ranges DN40 to DN900. The disc can be Dual-Plate and Single-Swing type; Soft Seat is commonly made of NBR or EPDM;Spring can be Stainless Steel 304 or Inconel 750;All valves will be Fusion bonded epoxy coated.

The cast iron check valve is made of cast iron material, and its inner cavity is equipped with a clamping spring, which is used to control and adjust the flow direction of the pipeline medium, and can realize one-way flow and prevent the backflow of the medium. Cast iron check valve is mainly used in liquid, gas, steam and other media pipeline system. The general working temperature is between -10℃ and 150℃, and the working pressure is generally between 0.1MPa and 2.5MPa.

Its key benefits are as following:

1.Halve Disc is positioned in the body rubber seats and provides 100% tight sealing.

2. Spring provides more force to disc, to achieve better sealing and fast close.

3. With eye screw (hook), easy to install between two flanges.

4. Can be installed in horizontal or vertical position.

5. Compact design,reduce the cost of valve,

6. Upper and lower PTFE thrust bearings