Features:

Leflow’s is manufacturing ball check valve with Flanged and Screwed ends, and options are as following:

1.DN15 to DN50 can be Screwed, and DN40 to DN600 are commonly flanged ends;

2.The coating of ball can be NBR or EPDM;

3.All sizes of valves are Fusion bonded epoxy coated;

4.Full bore for all sizes;

The cast iron ball check valve is usually used to control the one-way flow of fluids.

It usually consists of a valve body, ball, spring, and sealing components.This kind of valve is suitable for medium and small diameter pipelines and widely used in industrial systems such as water supply, drainage, heating, and cooling.

Its main characteristics are as following:

1.Simple and compact structure: fewer components, easy to install and maintain;

2.Low Pressure drop, Minimum backpressure for tightness 0.3bar;

3. Quick close:The check valve can quickly close when the fluid flow direction changes, preventing backflow and protecting the safe operation of the pipeline system;

4. Good sealing performance: The ball is encapsulated with soft rubber, which can achieve Zero leak;

5. Silent operation the sound of ball touching the seat is very small,as soft rubber covering the ball;

6. The ball can self-Cleaning;

7. Horizontal and vertical installation in the pipeline

8. Keep valve on Pipeline to change ball or clean valve interior

The Cast Iron Check Valve is engineered as a reliable Ball Check Valve and functions as an Automatic Check Valve, ensuring One-Way Flow Valve performance in various systems. It also operates as a Non-Return Valve and serves as a Backflow Prevention Valve, featuring a design that incorporates a Full-Flow Check Valve and a Non-Slam Check Valve to optimize fluid dynamics. This Pipeline Check Valve and Industrial Check Valve are built with a durable Cast Iron Valve construction, making it an ideal Fluid Control Valve for demanding environments. Moreover, it is widely used as a Water Treatment Valve, where proper Valve Installation & Maintenance is critical, and its detailed Valve Technical Specifications ensure precise performance in specialized applications.

We offer a wide selection of high-quality valves, including the cast iron ball check valve and ductile iron ball check valve, designed for reliable performance in various applications. Our black iron ball valve provides excellent durability, making it suitable for both industrial and commercial use. Additionally, our cast iron check valve is engineered to ensure smooth operation and long-lasting service in demanding environments.

If you have specific questions about their application or need further details, feel free to ask!

Cast Iron Ball Check Valve offers durable and reliable one-way flow control, ideal for water, wastewater, and general industrial systems. With its robust cast iron body and precision ball mechanism, it ensures long service life and efficient backflow prevention.

Reliable Backflow Prevention

This Ball Check Valve is designed for silent operation and minimal pressure drop. It provides consistent sealing under various flow conditions. Available types include:

-

Flanged Ball Check Valve

-

Threaded Ball Check Valve

These options allow flexible installation across pipeline systems.

Special Variants Available

We provide specialized configurations to meet different project needs:

-

Ball Check Valve with Spring – Enhances closure performance, especially in vertical flow systems.

-

Ball Check Valve with Rubber Seat – Offers tight sealing and noise reduction.

-

Cast Iron Valve with Stainless Steel Ball – Improves corrosion resistance in aggressive environments.

Wide Application Fields

The Cast Iron Ball Check Valve is used in diverse industries, such as:

-

Cast Iron Ball Check Valve for Water Supply

-

Cast Iron Ball Check Valve for Wastewater Treatment

-

Ball Check Valve for HVAC Systems

-

Ball Check Valve for Pump Protection

-

Ball Check Valve for Oil and Gas

-

Ball Check Valve for Chemical Industry

-

Cast Iron Ball Check Valve for Fire Protection Systems

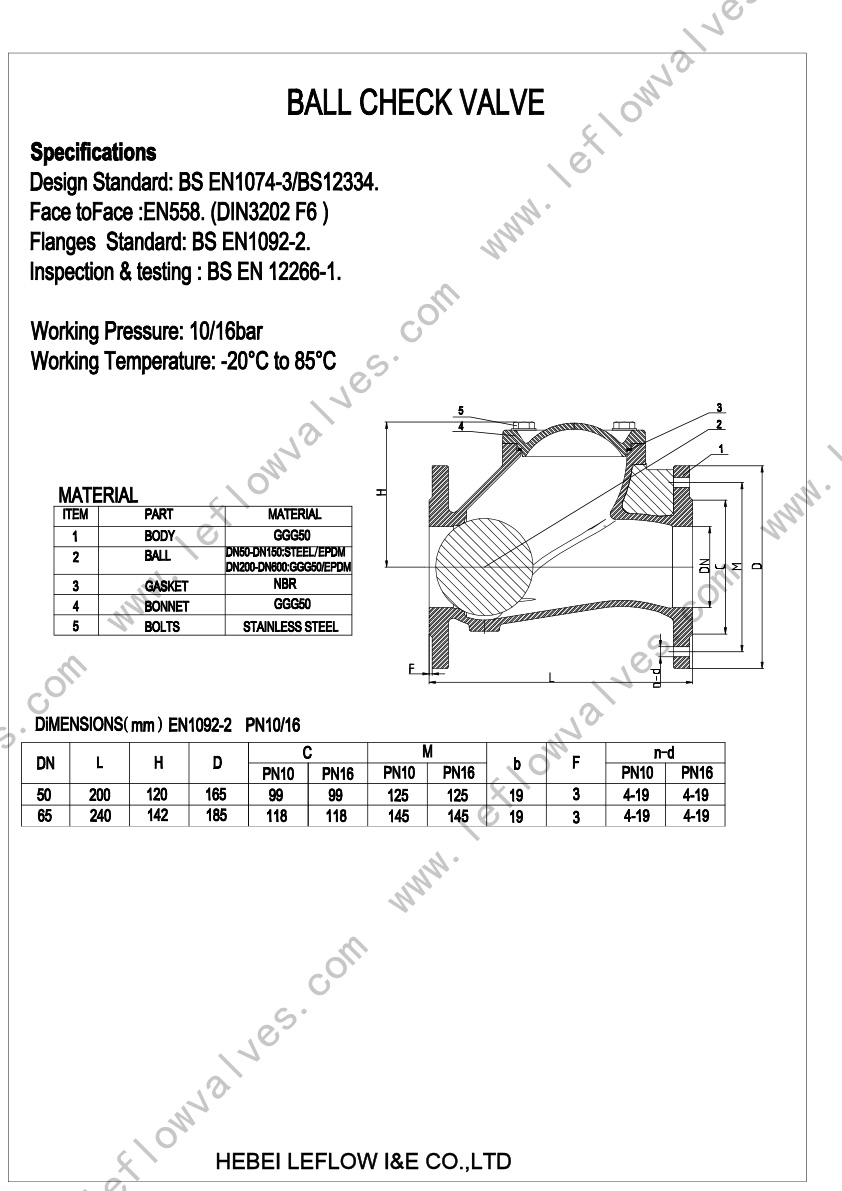

Specifications and Standards

We offer a full range of models and sizes, including:

-

Cast Iron Ball Check Valve DN50 DN100 DN150

-

Cast Iron Ball Check Valve PN16 PN25

-

Flanged Cast Iron Ball Check Valve

-

Threaded Cast Iron Ball Check Valve

-

BS EN 12334 Cast Iron Ball Check Valve

-

ISO Certified Cast Iron Ball Check Valve

Procurement and Custom Options

As a professional Cast Iron Ball Check Valve Supplier and Manufacturer, we support:

-

Wholesale Cast Iron Ball Check Valve

-

OEM Cast Iron Ball Check Valve customization

-

Competitive Cast Iron Ball Check Valve Price