Features:

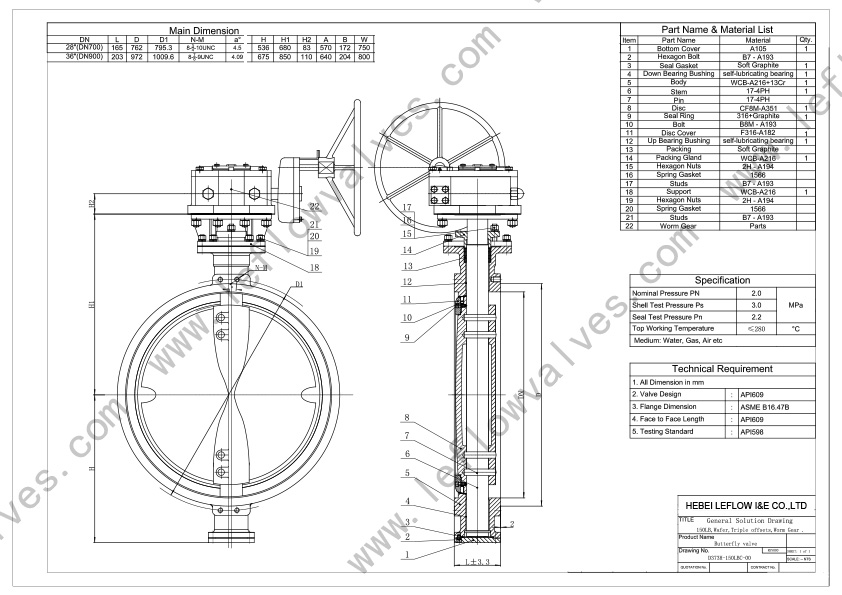

Leflow are providing 3-offset butterfly valve with Wafer, Lug and Double Flange type, The seat can be 13Cr, Stellite and other hard metal, The filler of disc gasket can be SS304,SS316, Monel and other alloys. Bidirectional seal can be reached on request.

Triple offset uses three separate offsets to achieve a bubble-tight. One of the offsets is the location of the valve shaft relative to the centerline of the bore. Another offset is between the centerline of the disc/seat sealing surface and the shaft. Then, the third offset is the geometry of the seating surface, which creates a cone shape of the disc and seat.

The structure gives valve following key benefits:

1.Eccentric structure ensures low operating torques with zero leakage performance.

2.Low moments are obtained by decreasing the friction through self-lubricating bushings.

3.high temperature and pressure adaptability.

4.Reduces the pressure loss through the disc designed in accordance with the direction of flow

5.Sealing gaskets made of Graphite filled with Stainless steel, which can achieve better sealing and long time use.

6.Retaining ring is assembled to the disc with imbus bolts, the disc is protected against corrosion by placing o-rings under the bolts.

7.simple to operate and easy to maintain

8.The seat can be several types of hard material, wide application and long time life.

Triple eccentric butterfly valves, also known as triple offset butterfly valves, are characterized by the valve stem axis being offset from both the center of the disc and the center of the valve body. Additionally, the rotation axis of the valve seat is angled relative to the axis of the valve body channel.

Triple eccentric butterfly valves are widely used in industrial pipelines, including those in metallurgy, electric power, petrochemicals, water supply and drainage, and municipal construction, where they serve to regulate flow and shut off fluid flow.

The application range of triple eccentric butterfly valves includes pressure ratings from PN16 to PN160 and Class 150 to Class 900, achieving a leakage rate of 0, and providing a high control ratio of over 100:1. In other words, in various harsh and critical process control pipelines, whether for on-off or control purposes, properly selected triple eccentric butterfly valves can be confidently used, providing reliable performance at a low cost.