Understanding the differences between various ball valves can be challenging due to the wide range of options available. Two key features to focus on are the port size and the construction of the valve. In this blog, we’ll dive into these properties and explore the types available.

PORT SIZES EXPLAINED

Port size refers to the size of the opening through which fluid flows when a ball valve is fully open. Ball valves typically come in three port size types: full port, standard port, and reduced port.

Full Port

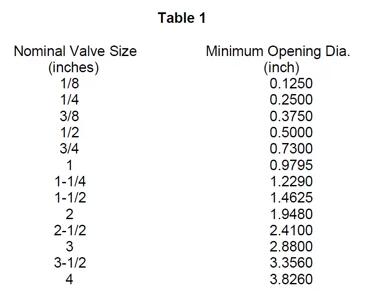

A full port ball valve allows unrestricted fluid flow because the opening in the ball matches the pipe’s diameter. To qualify as a full port valve, the opening must meet the minimum diameter requirements outlined in IAPMO IGC 157-2009. Achieving this design involves using an oversized ball, which makes the valve larger overall. Table 1 highlights the minimum opening diameters required for a valve to be classified as full port.

Standard Port

In a standard port ball valve, the opening in the ball is smaller than the pipe’s diameter, resulting in some flow loss. However, standard port valves are more compact since the ball itself is smaller, making them a more space-efficient option.

Reduced Port

Reduced port ball valves have an opening that is one pipe size smaller than the valve’s pipe size. This design reduces the flow capacity compared to the pipe itself. Reduced port valves are often grouped with standard port valves due to their similar flow characteristics.

UNDERSTANDING BALL VALVE CONSTRUCTION

The construction of a ball valve refers to how its components are assembled, which often depends on the desired port size. Construction methods affect the valve’s durability, performance, and cost. Let’s explore the main types of ball valve construction.

One-Piece Construction

In a one-piece ball valve, the connection ends are formed as a single solid piece, with the ball inserted from either the top or bottom. This seamless design eliminates weak points where leaks might occur. However, one-piece ball valves are always standard port because the design restricts the size of the ball that can be used.

Two-Piece Construction

Two-piece ball valves consist of two separate body pieces that allow for easier installation of the ball and seats. This design enables the use of a larger ball, making it possible to create full port ball valves. While effective, the seam where the two pieces connect can be a potential weak spot if improperly installed. Two-piece valves are among the most common types due to their full flow capabilities and versatility.

Three-Piece Construction

Three-piece ball valves are assembled by bolting together three separate components after the ball and seats are installed. These valves are highly durable and repairable, making them ideal for heavy-duty applications. However, the added complexity and material costs make three-piece ball valves significantly more expensive, which may not always be cost-effective for all uses.

Molded-in-Place Construction

Molded-in-place refers to the unique construction method used for PVC ball valves. In this process, the ball and stem are positioned in the mold, and heated resin is injected around them to form the valve body. This seamless construction results in a durable one-piece design without the seams found in other construction types, offering both strength and reliability.

Conclusion

While some construction differences in ball valves may not be immediately visible, understanding their design and functionality is crucial for selecting the right valve for your application. By considering the port size and construction method, you can make more informed decisions and choose a ball valve that best suits your needs. With so many options available, finding the perfect balance of performance, durability, and cost is easier when you know what to look for!