Features:

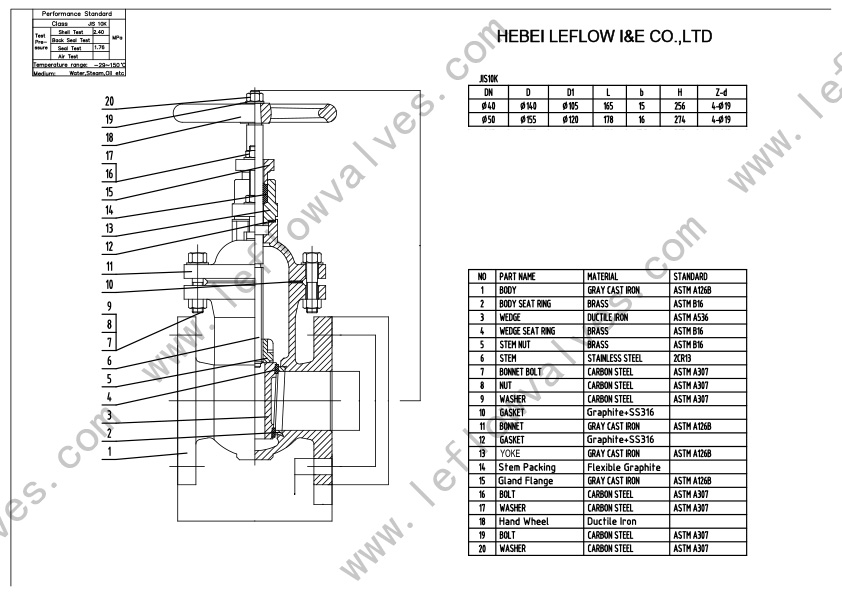

Leflow’s JIS Metal Seat Cast Iron Gate valve has following option:

1.Both Rising stem and Non-rising stem are available;

2.Seat can be Brass,Bronze and Stainless Steel;

3.Paint and Fusion bonded epoxy coating are available;

Metal seal cast iron gate valve is widely used in piping systems. The valve body and bonnet are made of cast iron, and the sealing surface is made of Metal materials such as stainless steel or copper alloy to ensure reliable and durable sealing performance. The Metal seal gate valve is mainly suitable for high temperature, high pressure, corrosive media and some high-strength fluid pipelines, common applications include chemical industry, petroleum, metallurgy, electric power, ships and other fields. The temperature range of the applicable medium is -40℃ to 120℃, and the maximum working pressure is up to 1.6MPa.

Its key benefits are as following:

1.Excellent sealing performance: The sealing surface of the Metal seal cast iron gate valve ensures a reliable and tight seal, preventing any leakage or fluid loss during operation.

2.Corrosion resistance: Cast iron valve body has good corrosion resistance, suitable for a variety of harsh environments.

3.Easy operation: The design of hand wheel or electric actuator makes the valve easy to operate and can achieve accurate flow control.

4.Durability and long life: the sealing surface is made of Metal material, which enhances the durability of the valve

Metal Seat Cast Iron Gate Valve Solution provides a robust, cost-effective, and reliable way to control flow in industrial applications where durability and sealing integrity are crucial. It offers significant advantages in high-pressure, high-temperature, and corrosive environments, making it ideal for water supply, oil and gas, chemical processing, and power plant applications. However, its weight and lack of throttling control should be considered depending on the specific needs of the application.